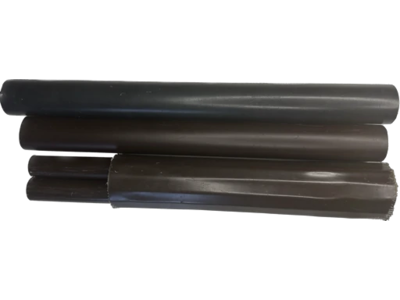

Cable lugs are used to connect cable cores to conductive busbars. Bolt terminals with shear bolts, manufactured by Termofit LLC, are suitable for cables with both aluminum and copper conductors.

Types of tips:

- Type A - Angled blade. On by default

- Type B - Straight blade, off-center. Made to order

- Type C - Straight blade in the center. Made to order

Bolts:

- Made from brass or aluminum

- They have 1 groove, the moment of breaking the bolt head is calculated based on the cable cross-section to ensure optimal electrical and mechanical connection. If necessary, bolts with 2 grooves can be made (so that when tightening the cores of the maximum cross-section, there is no need to saw off and grind the remains of the bolt “body”).

- At the contact spot in the bolt tips, a conductive lubricant developed by specialists from Termofit LLC is applied.

- The arrangement of the bolts can be in-line (standard design), V-shaped (mainly for stranded conductors), in-line, double-sided (from 600 mm2) or in a circle (“hedgehog”, for cables from 110 kV)

Sleeve:

- The body (sleeve) of the tips is made of aluminum alloy. If necessary, you can make a Tin-Bismuth (Sn-Bi) coating (electroplating), chemical oxidation or nickel plating - an electrochemical method of protection from adverse external influences, a thin film protects parts from chemicals and moisture and extends the service life of the product .

- There is a grooved knurling on the inner surface of the tip body, which increases the area and mechanical strength of the contact connection.

- Cable lugs have a hole that matches the geometry of the cable conductor.

- For cables with a cross-section of 35 mm2 and above, lugs with a special locking groove are used, which is necessary to prevent moisture ingress and oil leakage (on cables with oil-impregnated insulation), which is additional protection for the end coupling.

Documentation:

- TU 3599-016-23135464-2007

Individual approach:

- If there is no tip on the website that meets the required technical characteristics, contact the Termofit specialists and they will design a product according to your request

To increase the efficiency of the installation process, we recommend using tools 🔗 from the Termofit company.