Bolted connectors with shear bolts, manufactured by Termofit LLC, are suitable for cables with both aluminum and copper conductors.

Bolts :

- Can be made of brass or aluminum alloy.

- They have 1 groove, the moment of breaking the bolt head is calculated based on the cable cross-section to ensure optimal electrical and mechanical connection. If necessary, bolts with 2 grooves can be made (so that when tightening cores of the maximum cross-section, there is no need to saw off and grind the remains of the bolt “body”).

- At the contact spot in the bolted connectors, a conductive lubricant developed by specialists from Termofit LLC is applied.

- The arrangement of bolts can be in-line (standard design), V-shaped (mainly for stranded conductors), in-line, double-sided (from 600 mm2) or in a circle (“hedgehog”, for cables from 110 kV)

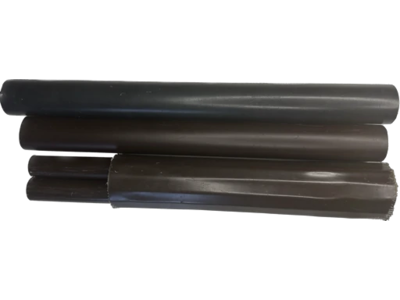

Sleeve:

- The connector body (sleeve) is made of aluminum alloy. If necessary, you can make a Tin-Bismuth (Sn-Bi) coating (electroplating), chemical oxidation or nickel plating - an electrochemical method of protection from adverse external influences, a thin film protects parts from chemicals and moisture and extends the service life of the product .

- There is a grooved knurling on the inner surface of the connector body, which increases the area and mechanical strength of the contact connection.

- Cable connectors have a hole that matches the geometry of the cable conductor.

- For cable joints with oil-impregnated paper insulation, locking connectors are used. In this case, the sleeve body has a partition, which prevents oil from flowing from one cable to another.

By special order, Termofit LLC produces:

Transition connectors: used to connect cables with different cross-sections.

Branch connectors: used when it is necessary to connect a branch cable to the main cable.

Repair connectors: differ from ordinary ones in their elongated size.

Documentation:

- TU 3599-016-23135464-2007

Individual approach:

- If the website does not have a connector that meets the required technical characteristics, contact the Termofit specialists and they will design a product to suit your request

To increase the efficiency of the installation process, we recommend using tools 🔗 from the Termofit company.